In today's fast-paced market, optimizing logistics freight is essential for robust supply chain management. Efficient logistics freight ensures products arrive on time and costs remain low. Companies face many challenges in this area.

Transportation delays can disrupt the supply chain. These delays often arise from poor planning or unforeseen circumstances. Many logistics providers struggle with real-time communication, leading to inefficiencies. Accurate tracking systems could address this issue, but adoption remains slow.

Moreover, the complexity of supply chains adds to the challenge. With numerous stakeholders involved, coordination can be tricky. Errors in freight management can lead to increased costs and unhappy customers. Reflecting on current practices may reveal areas for improvement. Ultimately, optimizing logistics freight is not just beneficial; it's necessary for survival in a competitive landscape.

Understanding logistics freight is crucial in today’s supply chain management. It involves coordinating the movement of goods from one location to another. Efficiency in logistics can lead to reduced costs and better service delivery. This requires a good grasp of transportation modes, warehousing, and inventory management.

In supply chain management, timely shipments matter. However, delays can happen due to various reasons. Weather conditions, vehicle breakdowns, or last-minute route changes can disrupt plans. Keeping communication open with logistics partners helps mitigate these issues. Reflections on past disruptions can lead to better planning in the future.

Another aspect is understanding the role of technology. Many companies employ software to track shipments and optimize routes. Yet, reliance on tech can backfire if the system fails. Balancing human oversight with technology is essential. Continuous improvement in logistics is a journey. Identifying weaknesses will make the supply chain stronger.

Efficient supply chain management relies heavily on optimized logistics freight. To achieve this, businesses must identify crucial factors affecting freight logistics. One significant aspect is route optimization. Shortening delivery routes can save costs and time. However, sometimes chosen routes might not be the best under changing conditions.

Another vital factor is load consolidation. Combining shipments can enhance efficiency and reduce transportation costs. However, businesses often struggle with balancing cost and speed. Too much focus on reducing costs may lead to extended delivery times, frustrating customers. Flexibility in adjusting freight operations is necessary to navigate these challenges.

Data analytics plays a crucial role. Gathering data on shipping patterns helps in making better decisions. Yet, reliance on data can lead to over-seeking perfection and ignoring practical adjustments. Real-time tracking is also essential. Knowing shipment locations can prevent delays and improve service quality. Yet, not all companies have the resources to implement these systems effectively, leading to gaps in efficiency.

| Optimization Factor | Description | Impact Level (1-5) | Priority (High/Medium/Low) |

|---|---|---|---|

| Route Planning | Improving delivery routes to reduce travel time and costs. | 5 | High |

| Load Optimization | Maximizing cargo space utilization to reduce shipping costs. | 4 | High |

| Technology Adoption | Utilizing software systems for tracking and management. | 5 | High |

| Supplier Collaboration | Working closely with suppliers for better inventory management. | 4 | Medium |

| Dynamic Pricing Strategies | Adjusting prices based on demand and supply fluctuations. | 3 | Medium |

| Third-Party Logistics (3PL) | Outsourcing logistics functions to specialized providers. | 4 | Medium |

| Sustainability Initiatives | Implementing green practices to reduce carbon footprint. | 3 | Low |

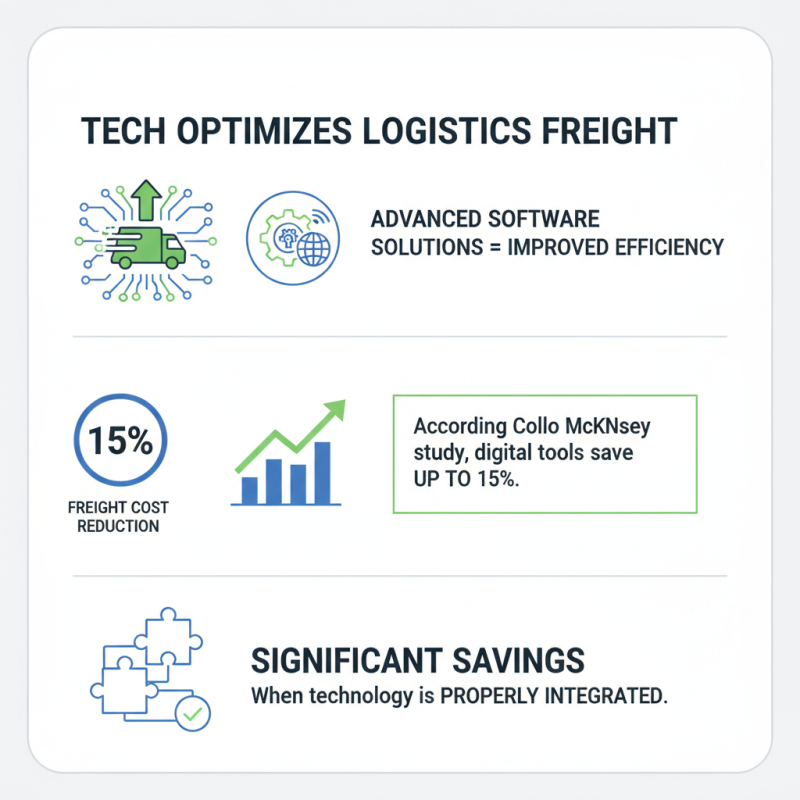

The role of technology in optimizing logistics freight is crucial. In recent years, the adoption of advanced software solutions has dramatically improved efficiency. According to a study by McKinsey, digital tools can reduce freight costs by up to 15%. This highlights the potential for significant savings when technology is properly integrated.

IoT devices play a key role in real-time tracking. These provide visibility of shipments, which is vital for timely deliveries. A report from Gartner indicates that 75% of companies prioritize real-time tracking in their logistics operations. However, implementation can be challenging. Many logistics managers struggle with data integration across various platforms. Consistency remains an issue.

Automation is another area ripe for optimization. Automated systems can manage inventory and scheduling, thus minimizing errors. According to the Logistics Management Association, automating processes cuts down operational costs by 20%. Yet, some companies hesitate. They worry about the initial investment and potential disruption during the transition. Balancing short-term costs with long-term benefits is a continuous challenge.

In logistics, measuring performance is critical for success. Companies often focus on metrics like delivery time, cost, and accuracy. However, not all metrics tell the full story. Sometimes, focusing solely on cost may ignore critical quality factors. This can lead to customer dissatisfaction and ultimately affect loyalty.

Continuous improvement relies on evaluating these metrics effectively. For instance, tracking delivery times can highlight delays. But what does that really capture? It might overlook other issues, like route inefficiencies or driver skill levels. Understanding the root causes of delays is essential for meaningful progress. Teams need to ask tough questions and dig deeper.

Employee feedback can provide candid insights. Workers on the ground often see problems that reports do not reveal. Listening to their experiences can guide adjustments. Regular review meetings could foster an open dialogue about obstacles and opportunities. Embracing a culture of improvement involves challenging conventional practices. It requires constant reflection and a willingness to adapt. A more holistic approach leads to better logistics performance.

Effective freight management requires strong collaboration with partners. The logistics industry relies heavily on partnerships. When stakeholders work together, it creates a streamlined process. Sharing information can reduce errors. For example, real-time tracking can enhance visibility. This allows better decision-making.

Tips: Establish clear communication channels. Regular updates help maintain alignment between partners. A shared platform can minimize misunderstandings.

Optimizing freight management involves evaluating existing relationships. Not all partnerships deliver value. Review performance regularly. Identify areas for improvement. Engage in open discussions about challenges. This transparency fosters trust and innovation. Monitor trends in the logistics sector to find new collaboration opportunities.

Tips: Consider joint training sessions with partners. These can boost understanding of each other's operations. Leverage technology for data sharing to enhance efficiency.